We combine cutting-edge technology with artisanal craftsmanship to produce high-performance composite boards for windsurfing, kitesurfing, SUP, soft boards, and foil boards.

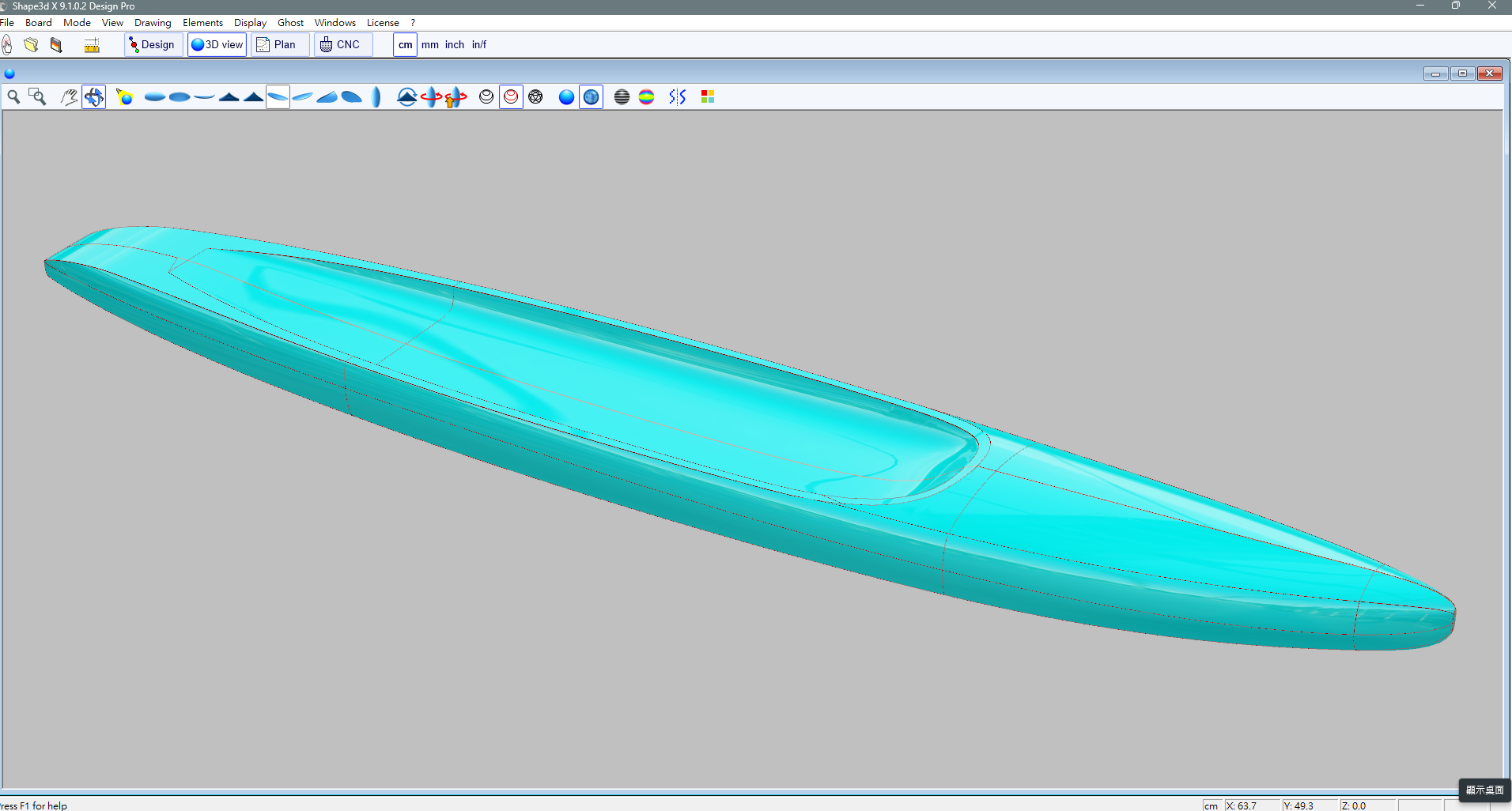

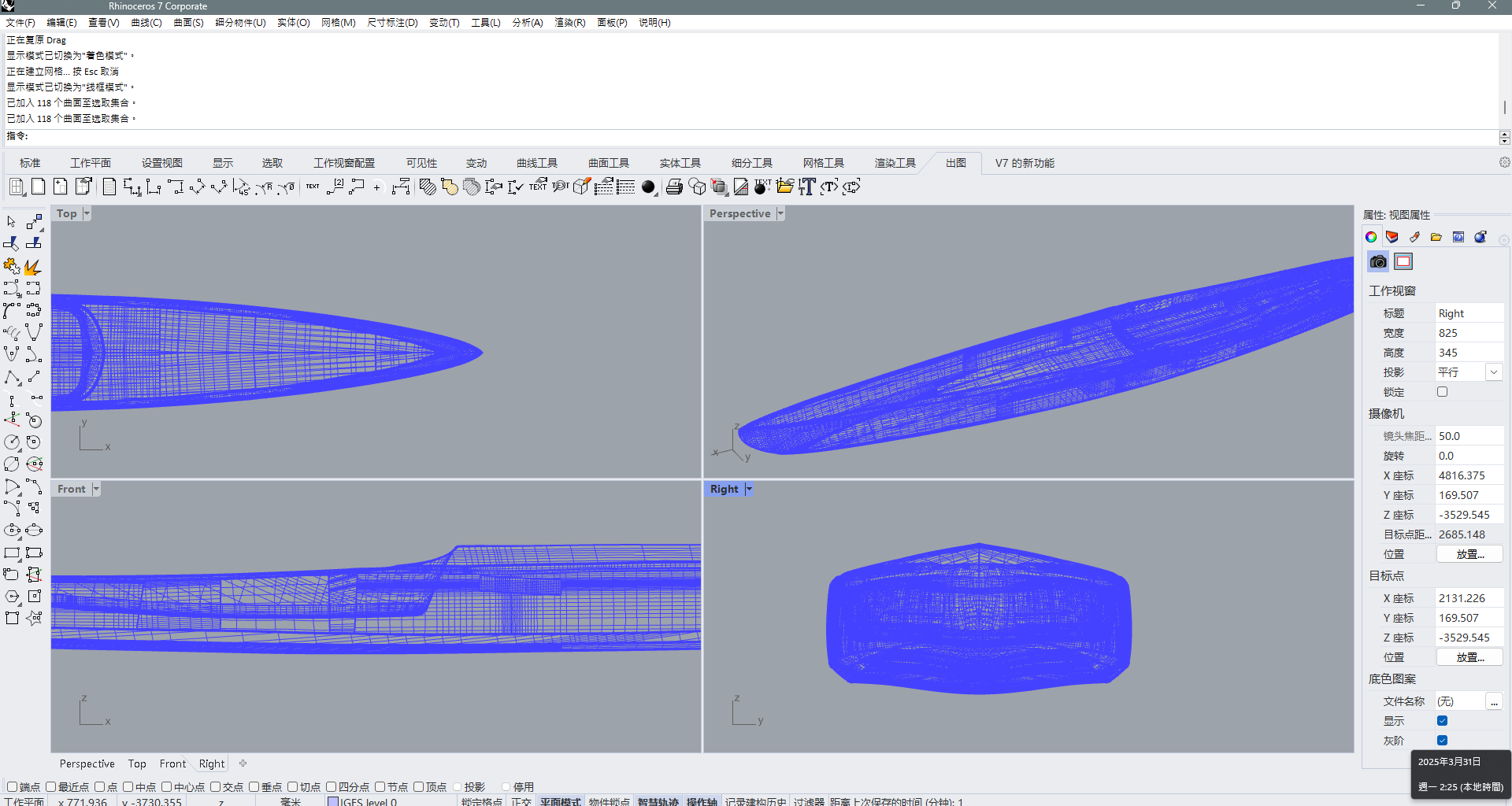

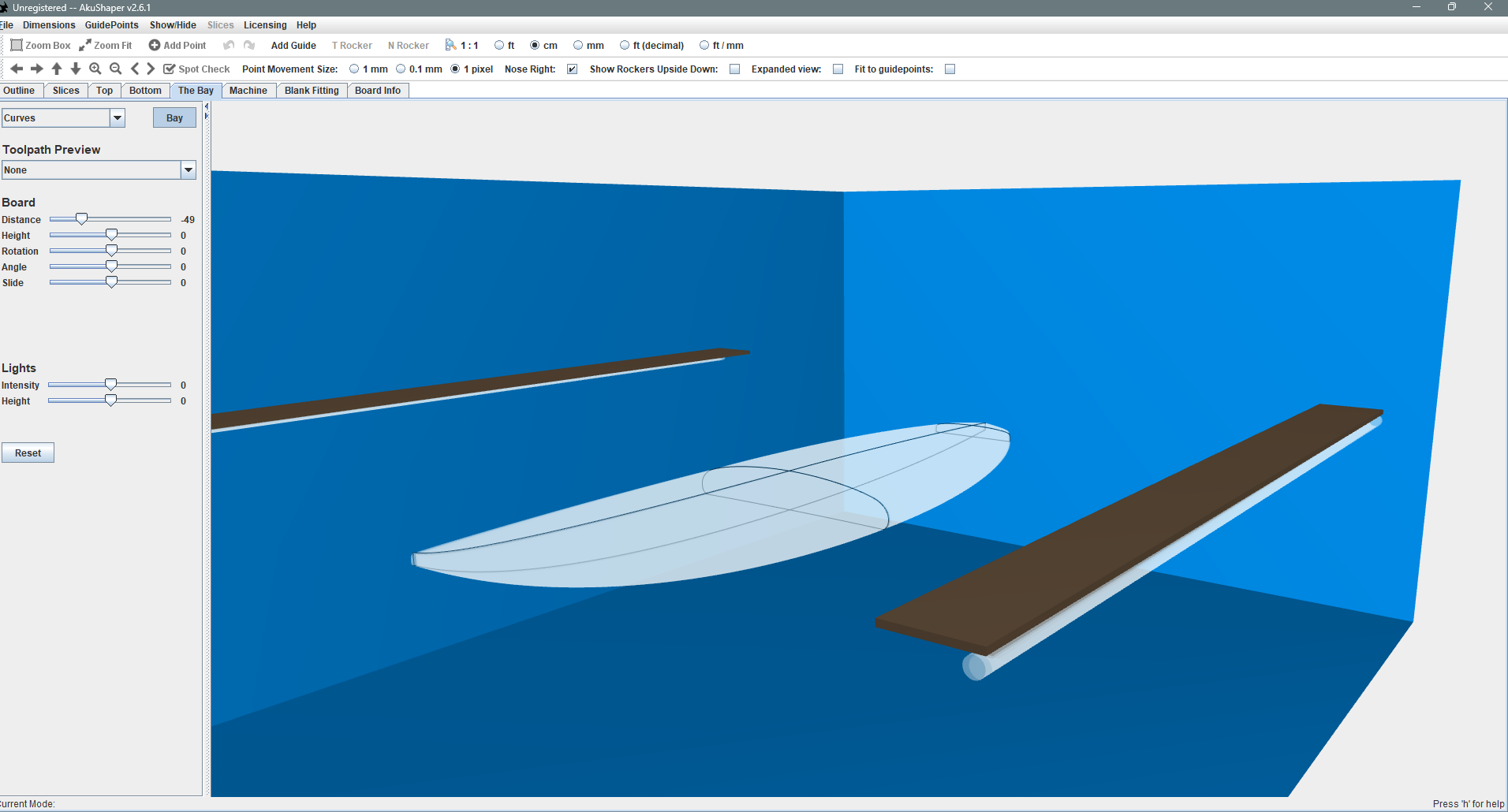

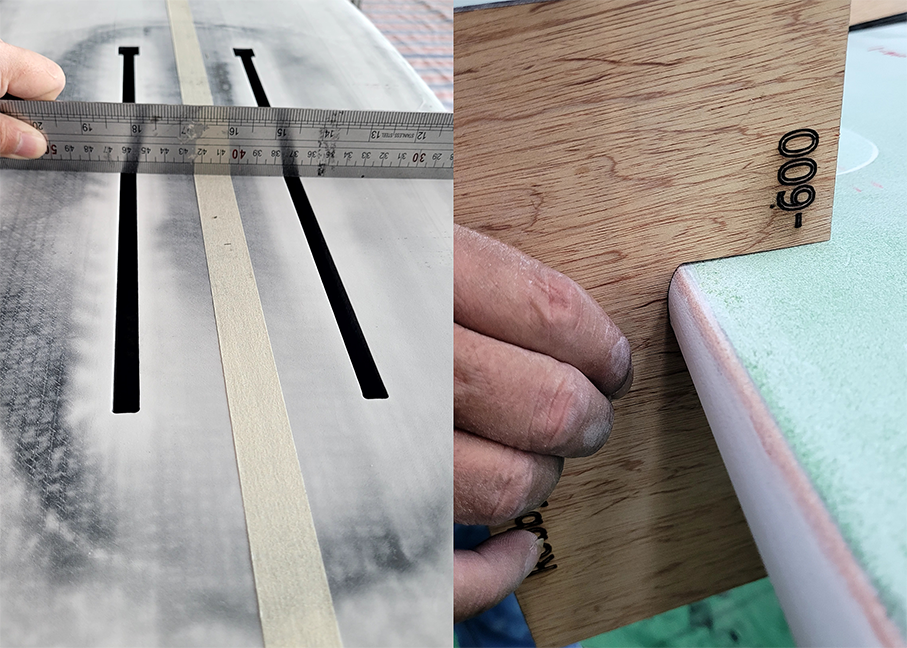

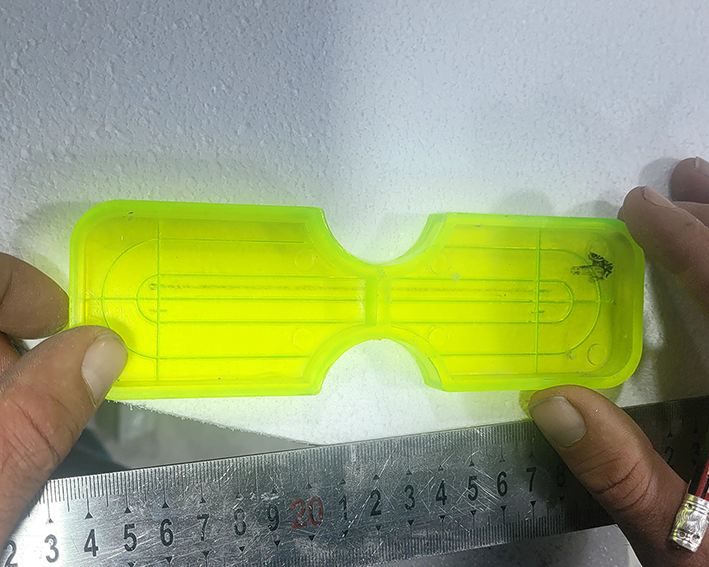

Shape Design & Validation

• Pre-Check Service: We meticulously review your design files for structural integrity, symmetry, and performance optimization to prevent costly errors before production.

• CNC Wooden Mold Fabrication: We craft precision wooden molds for foam validation, ensuring accuracy and quality at every stage.

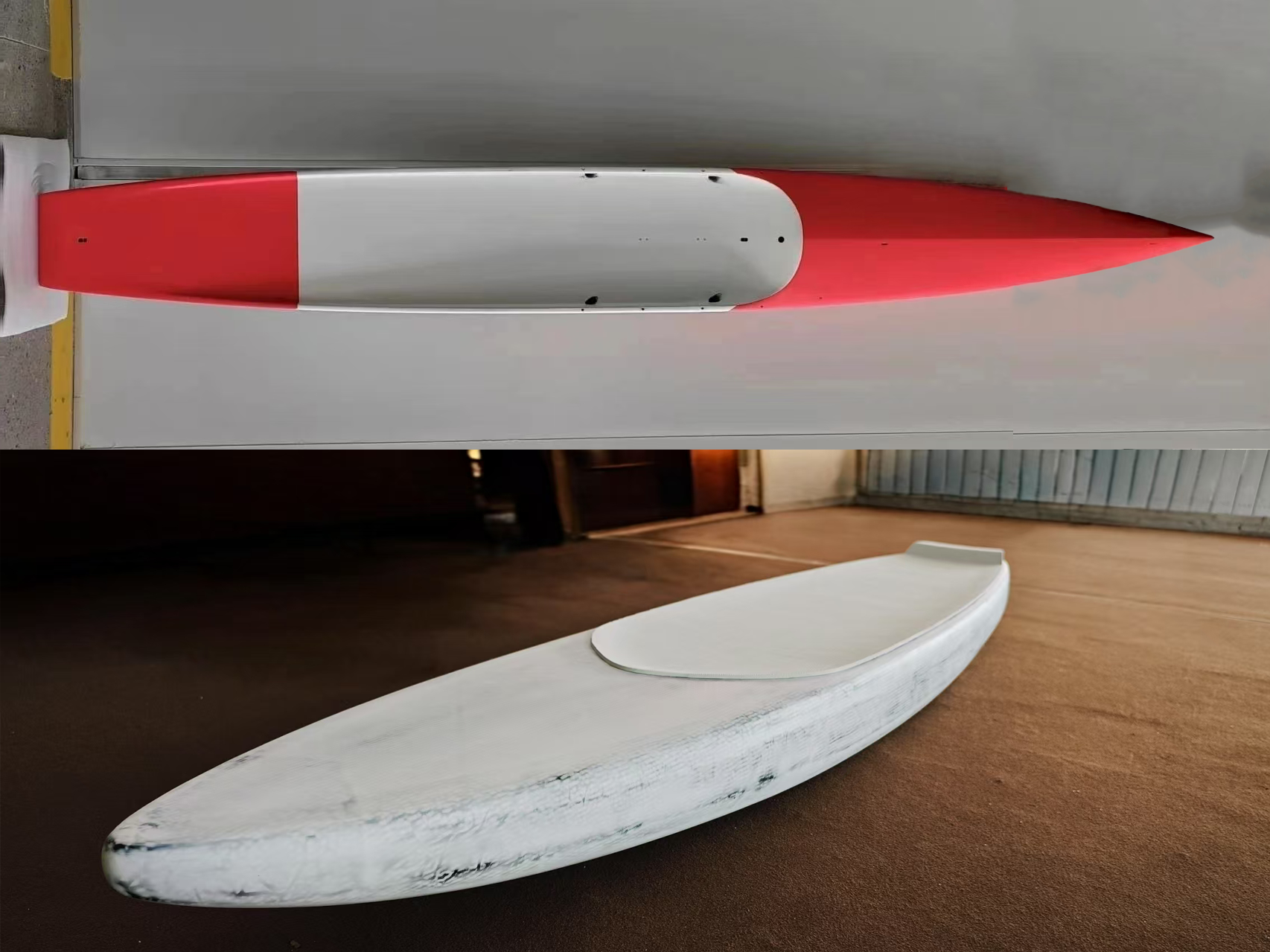

Composite Layup – Engineering for Performance

• Layup Consultation: Our experts can analyze or suggest layup constructions ( Carbon / Fiberglass / Kevlar ) to meet your weight/durability targets.

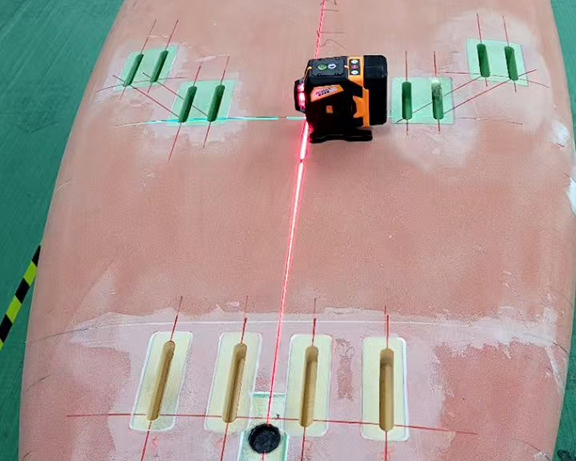

• Reinforced : All fin boxes/plugs are pre-installed PVC reinforcement as standard for impact resistance.

• Resin Control: Strict resin-to-fiber ratios are maintained to prevent excess weight while ensuring strength.

• Weight Tracking: weight reports at each stage (pre/post laminate, after glassing, etc.).

Painting & Graphics Perfect Detailing

•Laser Alignment: Laser pointers ensure logos/graphics are positioned to millimeter accuracy.

•Advanced Printing: UV-resistant inks and precision masking for complex designs.

Quality Control – Consistency You Can Trust

•Documentation: QC report with high-resolution photos sent before shipping.

•Pre-Shipment Inspection: Every board undergoes a 25+ point check (hardware alignment, weight tolerance, cosmetic flaws).

The C-Max Nova Advantage

- OEM/ODM Focus: We adapt to your brand’s specs, not the other way around.

- Transparency: process updates + complete records at every stage.

- No Surprises: You see exactly what’s shipped—before it leaves our factory.

- Competitive Edge: Premium quality at market-beating prices

Let’s build your next high-performance board—with precision you can trust.